MOOSEHEAD LAKE (Day 3 - part 2)

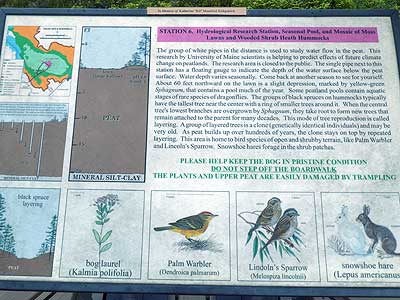

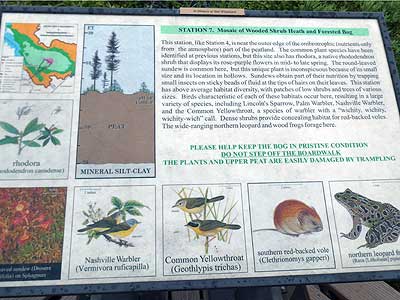

Sign 5 - Moss lawns (pink) - This area is extremely wet, with water just below or at the surface. Plants here are very stunted. Voles and shrews live here... as do the northern harrier hawks that eat them.

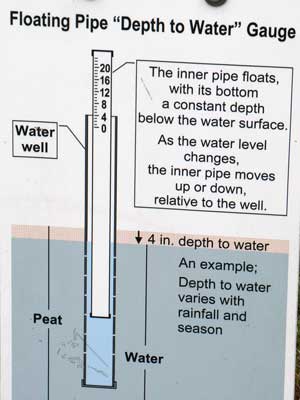

Sign 6 - Hydrological research station (also pink) - White pipes study the flow of water in the peat. The depth varies seasonally.

Sign 7 - Blend of wooded shrub heath and forested bog (light green and green) - As we made our way back, we once again crossed the different ecosystems.

A cedar waxwing

Our next stop was the Maine Forest and Logging Museum, located in Bradley. All the buildings were unfortunately closed so we just walked around outside. It was overcast and muggy but fortunately not raining.

The museum was founded in 1960 as a 1790s living history site to preserve and teach the history of how trees were harvested and milled before the days of steam power and electricity. Back then, the state was still part of Massachusetts (until 1820).

After the American Revolution ended in 1783, Massachusetts purchased land along the Penobscot River, including Township 4 Indian Purchase (which is now Bradley). Pioneers and settlers arrived from all 13 states. Some received land grants while others just squatted. An early settlement was established on Nichols Stream. It was later renamed Blackman Stream, after the Blackman Family who also ran a mill in the area through the late 1800s. There are the remains of a stone dam and the foundations of several houses. Oliver Leonard (1764 - 1828) bought this land around 1787 and established a mill.

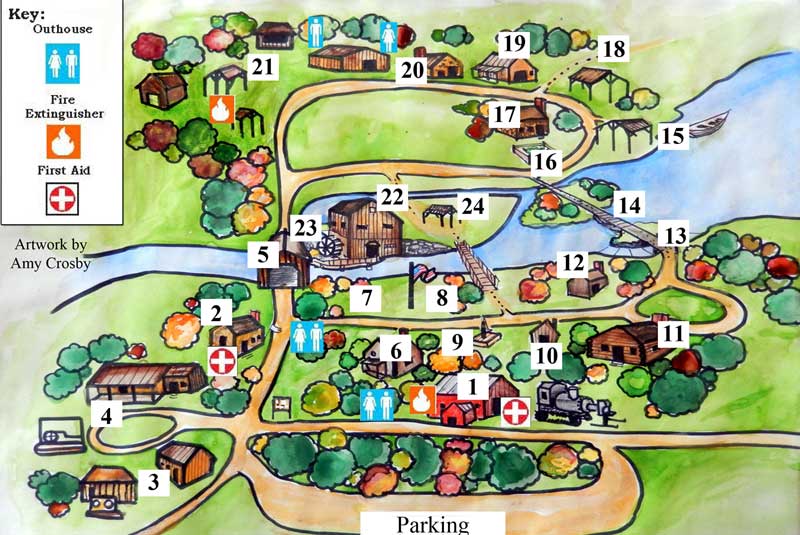

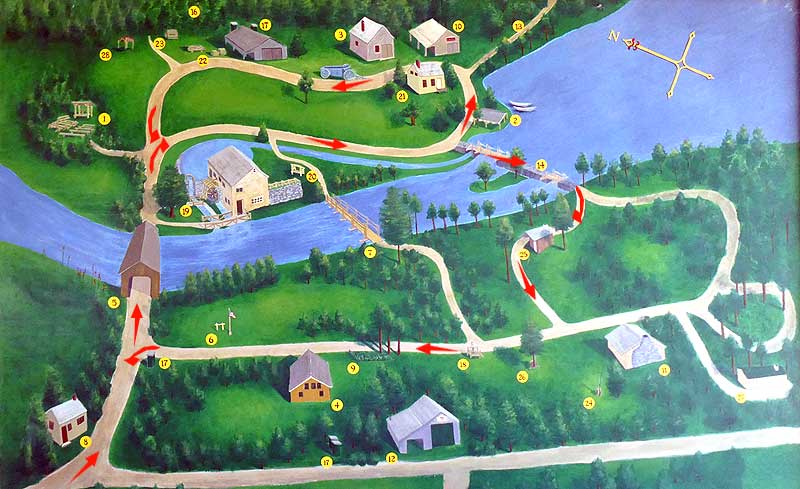

A map of the complex

We first headed to the visitor center (#1 on the map above). It was constructed in 2013 and dedicated to Allan Leighton (museum president from 1979 - 1992).

Outside there was a QR code that enabled us to watch of a film of the machine shop inside.

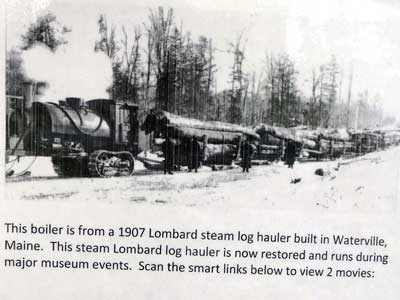

This boiler (the large round piece of metal) was from a 1907 Lombard Steam Log Hauler. This steam-power machine could move giant trains of logs through the forest. In winter, the front was mounted on skis.

We then followed signs to the 1920s saw mill complex. It had both a rotary sawmill and a shingle mill (numbers 4 and 3 on the map above).

This sawmill was typical of small Maine towns 50 to 100 years ago. Logs would be delivered to the mill and then cut into whatever was needed. It could handle logs up to 30 inches in diameter. This machinery, built in 1909, was brought to the museum in 2005.

The shingle mill, built about 100 years ago, is still fully operational. Made from white cedar, each shingle was sorted by quality.

We then crossed Blackman Stream to explore the mill and the rest of the complex.

The red arrows indicate the path we took.

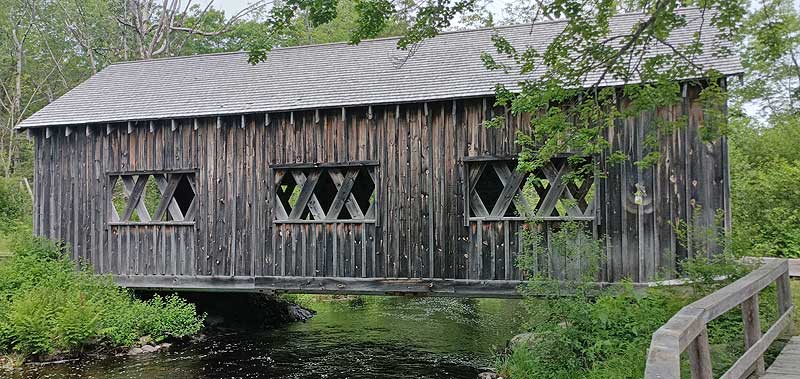

Bridges were not covered to protect the traveler but rather the timbers and planking of the bridge itself to keep water out of the joints. They were also possibly meant to trick horses and oxen into thinking they were entering a barn to prevent them from panicking at the sight of rushing water. This one is patterned after Ithiel Town's "lattice truss" developed in 1819. Made from short lengths of cross-timber, these bridges could bear tremendous weight.

The covered bridge from the side

Today, Leonard's Mills is the only operational water-wheel-powered "up and down" sawmill in Maine. The first up and down mill in Maine was built in 1634.

For 250 years, Maine settlers and farmers relied on water power as their principal source of mechanical energy. The power provided energy to perform tasks that were too difficult or tedious to do by hand. In the 1890s, there were perhaps as many as 10,000 waterwheels in North America. They were used to cut logs, spin wool, run the bellows for forges, grind grain into flour, mash apples for cider, process leather and paper, and numerous other tasks. Instead of having to built log cabins, settlers could now build frame houses. Communities were able to move from subsistence-level production into a market economy.

How the mill works:

The mill pond serves as the source of power. The water flows over the top of the waterwheel and into bucket-like sections. The weight of the water pulls the heavy side of the wheel down. At the center of the wheel is a power shaft which extends through the wall into the mill. This drives a series of complex wooden gears that lift (up) and lower (down) a saw blade. This is the only wooden geared mill in the US! This powers the saw to cut logs into boards.

The waterwheel. Note where the water would flow from the top, as well as the bucket-like sections in the wheel itself.

The mill pond

We followed the path to a carriage and boat shed.

As we learned at Old Fort Western, a batteau is a wooden riverboat with a flat bottom, flared sides and a long narrow bow and stern. it was used to move people and supplies down river and was commonly operated by six men. Four men rowed while the bowman and sternsman guided it. Here these boats were used to move logs on the lakes and rivers.

We rounded the end of the loop and walked among several large buildings.

This was an early settler's house, built using the "post and beam" type of architecture. Wooden supports were cut to precisely fit with other wooden supports. Once in place, the interlocking beams were then linked with a wooden peg. Early settlers did not have easy access to metal nails. The house was a big improvement over the cabins. It had wooden floors, paned windows and a separate sleeping area upstairs.

(left) This temporary barn is called a hovel. It was used to house oxen or horses while lumber workers operated in the woods. Most were built of logs and roofed with shakes. Some settlers lived in them until they were able to build a cabin. (right) Another carriage

The blacksmith shop. The tasks of the blacksmith included making and repair toes, shoeing horses and oxen, building and repairing wagons and sleds... and sometimes even pulling teeth. This one was originally built in the late 1800s by Harry Goodwin on his farm in Hudson (Maine). It was donated and rebuilt here in 1992. People sometimes think the word Smithy refers to the person, but it only means the shop or building in which the blacksmith worked.

The outhouse ... A wood-fired oven

We completed the loop, walked back past the watermill, and crossed the mill dam.

This site was chosen because of a natural narrow ledge and small drop in elevation, which could provide the mill with power.

The fishway allowed for fish to bypass the dam. This type of ladder is called a pool and weir system.

We continued on the path through the woods. There were several rather pesky flies that had decided to walk with us.

A settler's cabin. The entire family would live here until a real house could be built. .... A trappers cabin. These were short term shelters set up along a trapper's route or circuit. It had a pallet (or cot) and a rudimentary hearth on which to build a small fire for heat and light cooking. They were only used sporadically during the trapping season. it may have been used by trappers other than just the owner.

Replica of an 1840s smokehouse ... The wet path

A working water hand pump

return • continue